THE BATTERY INDUSTRY

Almost 8.5 billion euros of investment

major industrial projects related to batteries across the region

major logistics projects related to electric mobility across the region

direct jobs planned for industrial battery projects

DUNKIRK, AT THE HEART OF FRANCE’S BATTERY VALLEY

One of the major challenges standing in the way of reaching net zero emissions in France by 2050 lies in reducing greenhouse gas emissions, particularly in high emissions sectors such as energy (41%), transport (24%) and construction (24%), according to the International Energy Agency (AIE, 2021), on a global scale.

Electric car development seems to be a crucial solution to reducing these emissions. However, the matter of the strategic metals needed to manufacture electric batteries and their end-of-life recycling is a real challenge. In July 2023, the European Council adopted a new regulation aiming to promote the circular economy by regulating the life cycle of batteries. Ambitious recycling efficiency targets were set at 80% for nickel-cadmium batteries and at 50% for other battery waste for now to the end of 2025.

By 31 December 2031 at the latest, recycling as a whole should reach at least the following material recovery targets:

- 95% for cobalt

- 80% for lithium

- 95% for nickel

DUNKIRK, AN ECOSYSTEM ENCOURAGING THE EMERGENCE OF THE BATTERY INDUSTRY

The territory has many assets to its name:

- The 3rd largest port in France, boasting an excellent connection to logistics networks

- A strong industrial culture, a dynamic ecosystem

- Turnkey sites helping companies to get up and running quickly

- Effective cooperation between all the area’s stakeholders

- Raw materials (steel, aluminium) and low-carbon energy

200,000 tonnes per year of so-called “electrical” steel will be produced by ArcelorMittal Mardyck from 2024, representing a 300 million euro investment. This steel is intended for electric motors in general and is characterised by its magnetic and mechanical properties.

60,000 tonnes of alloy ingots for the automotive sector will be produced by Aluminium Dunkerque from 2025. Aluminium is used to make vehicles lighter.

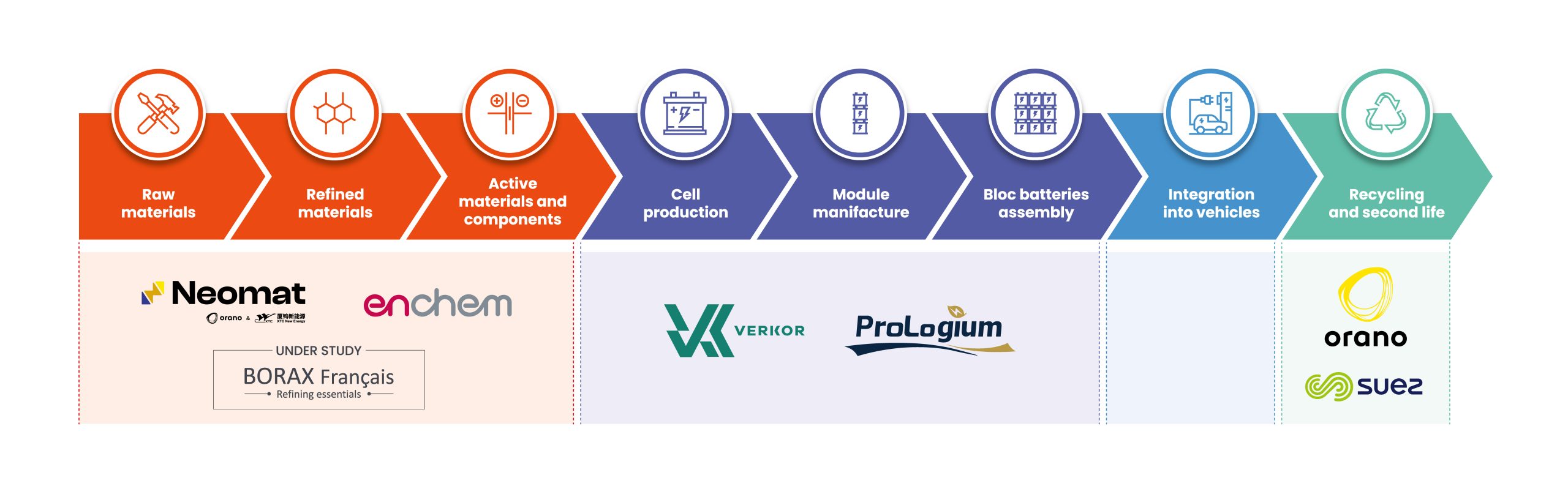

BATTERY VALUE CHAIN IN DUNKIRK

The value chain’s “upstream” activities in Dunkirk

- Refined materials production (electrolytes, lithium hydroxide):

- Enchem

- Project under study at Borax Français

- Battery component production such as the precursors and active materials of cathode, composed of nickel manganese and cobalt or lithium iron phosphate.

Battery production activities: cells, modules

The value chain’s “downstream” activities:

-

- Orano recycling

- Eramet – Suez recycling: collection, disassembly and grinding, blackmass treatment using a hydrometallurgy process

THE 7 MAJOR LOCAL INDUSTRIAL PROJECTS

NEOMAT

A co-entreprise between Oran and – XTC New Energy

Expertise: Orano, an internationally recognised expert in the nuclear fuel cycle.

Project: Orano and XTC New Energy have signed agreements with a view to creating two joint ventures involving the production of cathode active materials (CAMs) and their precursors (P-CAMs) for electric vehicle batteries, as well as a shared R & D laboratory.

When it comes to these two plants, which will be built on a 53 hectare site in Dunkirk, the two industrial groups plan to have mirror-image shareholding and governance: Orano will hold 51% and XTC New Energy will hold 49% of the P-CAM plant, and XTC New Energy will hold 51% and Orano 49% of the CAM plant. These plants will primarily use NMC (a combination of Nickel, Manganese and Cobalt) technology, which is mainly employed in Europe and essential for the production and performance of electric vehicle batteries.

Orano is also planning to set up and run a battery recycling factory on the same site near the P-CAM and CAM manufacturing facilities. This comprehensive project should help to create a complete and sustainable value chain in France and meet both France and Europe’s decarbonisation targets.

Completion dates: First commissioning: the CAM plant in 2027.

PROLOGIUM

Expertise: A global leader in the development and manufacture of the new generation solid state battery.

Project: Setting up a gigafactory for the production of solid state batteries for electric vehicles.

Completion dates: Work should begin by 2026, activities should be up and running in 2030.

Read the testimonial of Vincent Yang, CEO and founder of ProLogium:

VERKOR

Expertise: Low-carbon, high performance battery production.

Project: Setting up a production unit for electric battery modules intended mainly for the automotive sector.

Completion dates: Gradual commencement of activity in 2025 (1st phase), final completion in 2027.

BORAX FRANCE

Expertise: A long-established company in Dunkirk, Borax France converts boron oxides into speciality borates.

Project under review:

- In terms of historical business, the site has developed boric acids for the cathode market and is studying the installation of a new dedicated line.

- The group is studying the feasibility of opening a line for the production of up to 12,000 T of lithium hydroxide per year, an essential component in the manufacture of electric batteries. The current study is looking at the best options for integrating the new service, in order to optimise water consumption and meet CO2 emissions reduction criteria.

SUEZ

- Expertise: SUEZ – Lithium-ion battery recycling

Suez, a leader in circular solutions for water and waste, has chosen Dunkirk as its recycling factory for lithium-ion electric vehicle batteries. Production is due to start in 2026, subject to the final investment decision.

SUEZ specialises in the collection, sorting, preparation, dismantling and recycling of battery waste.: - An “upstream” factory for the dismantling and production of blackmass, a metallic concentrate of nickel, cobalt, manganese, lithium and graphite. Commissioning is set for 2026.

ENCHEM

Expertise: A leader in the production of electrolytes

Project: Setting up an electrolyte production factory for batteries, NMP recycling and cathode suspension production.

Completion dates: Construction is due to start in 2025, activities should be operational in 2027.

Key figures:

- 57 million euro of investment

- 100 direct jobs

- 5 hectares

- 150,000 tonnes of electrolytes