GAS, BIOGAS, LNG

largest LNG terminal in continental Europe

transhipment port by relative worth

tonnes of biomass from the Dunkirk area

MWh of potential energy from local biomass

GAS AND BIOGAS: TWO MAJOR AVENUES OF TRANSITION

According to French Agency for Ecological Transition ADEME, natural gas plays a key role in Dunkirk, accounting for one third of all industrial and residential energy requirements. The following comparison shows CO2 emissions by energy source:

- Natural gas (CH4): 227 grams of CO2 per KWh

- Electricity: 80 grams of CO2 per KWh

- Biogas: 44 grams of CO2 per KWh

These figures highlight why biogas and other types of renewable gas from various sources such as agriculture, the food industry and waste collection offer such a significant alternative to fossil fuels. Renewable gas is being used to tackle both economic and

environmental challenges, producing energy from waste and providing low-carbon solutions for transportation and industry.

Going forward, the gradual replacement of fossil natural gas by biomethane (biogas that has been purified and treated so that it has the same characteristics as natural gas) could eventually cut CO2 emissions by as much as fivefold.

Dunkirk has many biogas production resources leveraging innovative methods: pyrogasification, hydrothermal gasification and anaerobic digestion are currently being industrialised, offering a potential 40 MW of green gas from Dunkirk and the surrounding area – a major step towards achieving France’s ambitious aim of becoming carbon-neutral and thus strengthening the country’s energy independence.

LOCAL PROJECTS RELATING TO BIOGAS

Ch. Daudruy Van Cauwenberghe & fils

Daudruy launched Nord-Métha, an anaerobic digestion project, in July 2023. Drawing on oil refining and biodiesel production, the project can dispatch up to 875 Nm3/hr of biomethane into France’s national gas grid (operated by GRDF). That’s the equivalent of the annual gas consumption of 12,000 households, with avoided emissions of up to 12,000 tonnes of CO2 per year. Research into energy recovery from biogenic CO2 is also underway.

Read more about this anaerobic digestion project

(*Co-funded by the European Union through the European Regional Development Fund)

Flandre Biogaz

Flandre Biogaz has been producing biogas derived from livestock and crop waste from four local farmers since 2023, with an estimated 160-190 m3/hr of biogas being dispatched into the GRDF network.

GRDF

GRDF (which operates France’s natural gas grid) and GRTgaz (the carrier) are working with stakeholders across the green gas industry in Hauts-de-France as part of the Métha’morphose REV3 scheme. Together, they are carrying out three major studies in the Dunkirk urban area:

- Research into methane pyrolysis with the aim of converting methane into hydrogen and solid carbon without any CO2 emissions.

- Research into an oxy-fuel combustion boiler to capture and recover CO2 from combustion.

- Contribution to research headed up by Pôlenergie into green gas production inputs.

DUNKIRK: A KEY GATEWAY FOR FRANCE’S GAS IMPORTS

Dunkirk is one of France’s leading entry points for gas: not only is it where one of the largest underwater gas pipelines (operated by Gassco) makes landfall, it is also home to Dunkerque LNG, the second-largest LNG terminal in Europe with total LNG storage capacity of 600,000 m3 at -162 °C. As a result, it has a highly developed gas network.

DUNKERQUE LNG TERMINAL

- The terminal boasts total regasification capacity of 13 billion cubic metres per year (equivalent to 20% of the annual gas consumption of France and Belgium) making it the second-largest in continental Europe.

- Liquefied Natural Gas or LNG is an energy alternative to more polluting fuels in the transport sectors, both sea and road, and industry, thus contributing to the energy transition.

- In addition to LNG-related business, Dunkerque LNG is keen to play a long-term role in local development and meeting the region’s greenhouse gas emissions targets. Dunkerque LNG will be building on its expertise and infrastructure as well as potential synergies in the field of cold management to develop new business lines including CO2, ammonia and synthetic gas imports and exports, helping to reduce the carbon footprint of the port and its industries as it does so.

- In June 2025, Dunkerque LNG successfully completed its very first test loading of BioLNG into a Molgas tank, a vital step on the way to low-carbon heavy-duty transport. BioLNG is a 100% renewable gas derived from organic waste, produced at over 750 sites across France.

DK6 POWER STATION

Commissioned in 2005, DK6 is a 790 MW combined-cycle power station on the ArcelorMittal site in Dunkirk. Operated by Engie, it is powered by gas from ArcelorMittal steelmaking and natural gas produced at the Dunkerque LNG gas terminal.

At full capacity, the power station can provide all the electricity needed by the ArcelorMittal site – and inject the surplus into the national grid.

GLOSSARY

PYROGASIFICATION

A procedure that involves heating solid inputs (wood waste, solid recovered fuel) to over 1000 °C in the presence of very small quantities of oxygen.

This produces a synthetic gas that can then be purified and a residue known as biochar (used as fertiliser).

HYDROTHERMAL GASIFICATION

A thermochemical process at high pressure (210-350 bar) and temperature (400-700 °C) that uses water as a reagent to convert wet inputs (wastewater treatment plant sludge and industrial, urban and agricultural effluent) into a gas that can then be purified.

METHANATION

Production of synthetic methane (also known as e-methane) by combining dihydrogen (H2) and carbon monoxide or dioxide (CO, CO2) through a chemical reaction using a catalyst (usually nickel-based) or an organic reaction using bacteria (Archaea).

THE RISE AND RISE OF ANAEROBIC DIGESTION

- The Dunkirk area is home to both farming and industry, a distinctive feature providing many sources of biomass from agriculture and the food industry – an essential requirement for any anaerobic digester project. Household waste can be collected and used for anaerobic digestion, too. The Greater Dunkirk Urban Council (Communauté Urbaine de Dunkerque, CUD) and the Hauts de Flandre Greater District Council (Communauté de Communes des Hauts de Flandre, CCHF) are closely monitoring emerging private-sector projects in this field and committed to supporting them, facilitating administrative formalities and encouraging acceptability on the part of local residents. Four sites around Dunkirk have already started to operate anaerobic digesters: Nord Metha, Lievin Biogaz, SCEA Les Trois Chênes and Monsterleet. Several other projects are up and running too. They include:

- An anaerobic digester using refinery sludge and glycerol from biodiesel production at Ch. Daudruy Van Cauwenberghe & fils.

- A bio-gasification demonstrator (fuelled by non-recyclable plastic waste) at Econox.

A GROWING NUMBER OF SITES

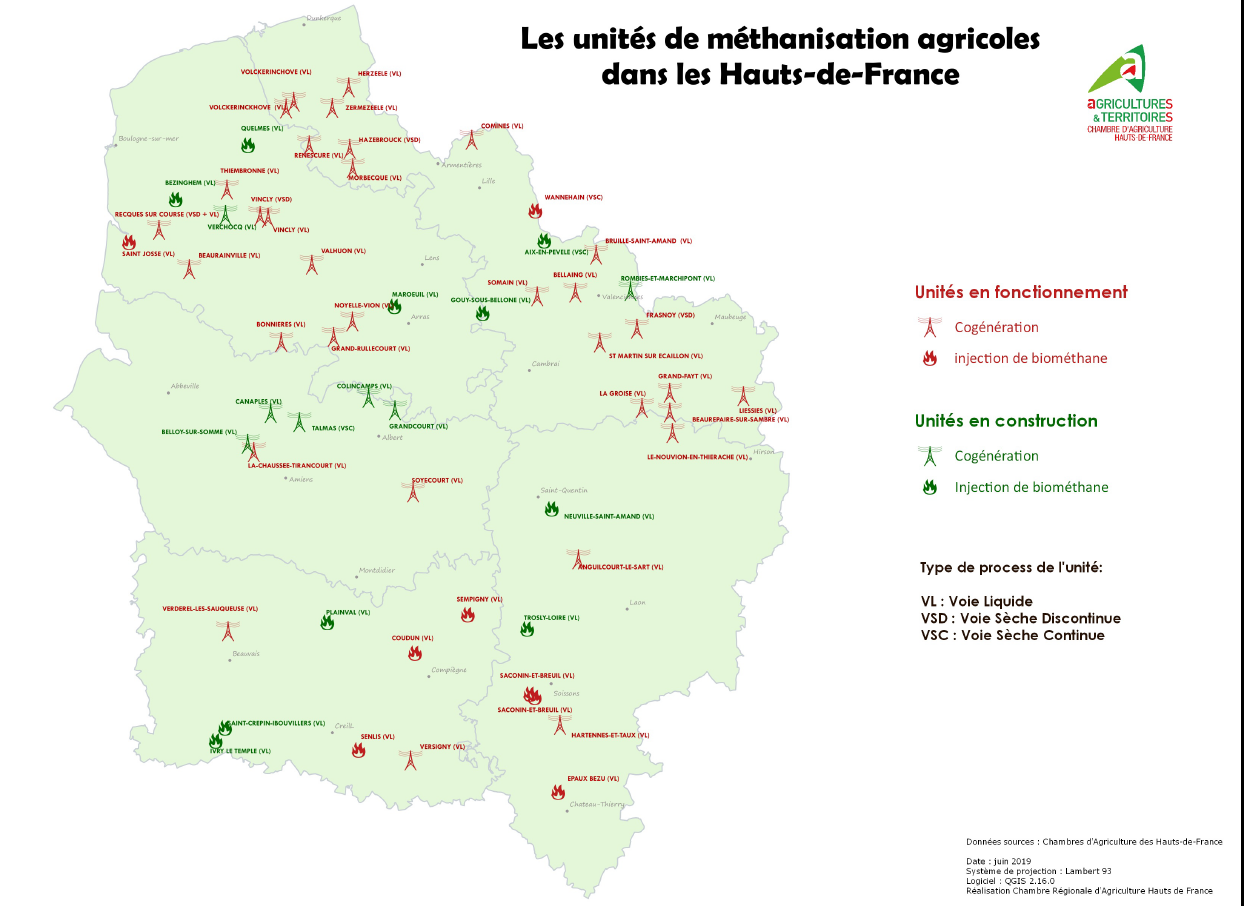

The idea of using livestock effluent, crop residues and the like to produce biogas is winning over increasing numbers of farmers. Some thirty anaerobic digesters are already in operation in Nord-Pas-de-Calais and one hundred and thirty projects are currently being developed across the Hauts-de-France region; these numbers are expected to continue to rise in the years to come, with major implications for the highly rural, southern part of the Dunkirk area.

“There’s a genuine interest in developing anaerobic digestion in Hauts-de-France, a region with extensive agriculture”.

The Hauts de Flandre Greater District Council and the Greater Dunkirk Urban Council are taking a close interest in all the projects of which they are aware. “There’s already a co-generation anaerobic digester in operation at Herzeele and two others on two different farms in Volckerinckhove. An anaerobic digester for dispatch into the grid is currently being planned on one of these sites. We’re also following two other projects at Wormhout and Quaëdypre