CO2

DUNKIRK: SOLUTIONS LAB FOR CO2 CAPTURE AND USE

The industrial and port platform of Dunkirk, France’s leading CO2 and H2 hub, is a pioneer in the quest for CO2 capture and reuse solutions.

- 16 MT of CO2 are emitted every year and constitute a recoverable co-product.

- Dunkirk and its hinterland are home to many CO2 decarbonisation and use projects. Reuze, DMX and D’Artagnan are just a few examples.

Dunkirk’s port and industrial area is the source of 21% of the French industry’s carbon emissions.

Dunkirk is aiming to become carbon neutral by 2050

The Dunkirk REUZE project will enable 300,000 tonnes of CO2 to be captured from the ArcelorMittal site.

The “3D” pilot will be able to capture around 4,400 tonnes of CO2 per year to treat the blast furnace gases from the ArcelorMittal factory in Dunkirk.

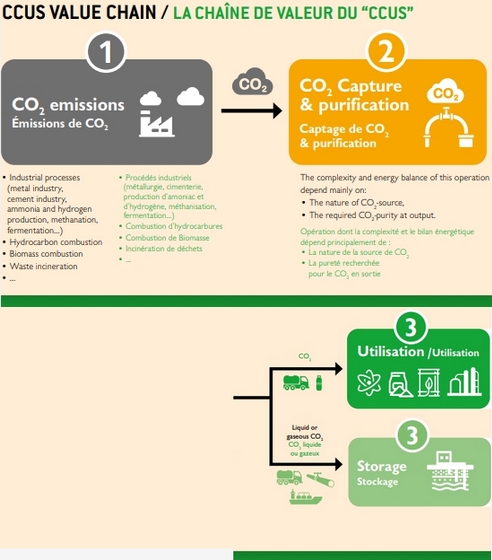

WHAT DOES CARBON CAPTURE, USE AND STORAGE (CCUS) INVOLVE?

Although reducing CO2 emissions remains one of the main objectives, other projects are underway or in the pipeline:

- CO2 capture and storage (CCS), such as the Northern Lights project.

- CO2 capture, use and storage (CCUS) with three major principles:

- Use without transformation,

- Chemical transformation,

- Biological transformation by bursting and recovering the

molecules forming the CO2.

To transform it, there are numerous parameters to be considered: the stability of the available resource, the grade of purity, the cost of the technologies and regulatory fees and other criteria linked to the planned transformation processes (availability of land, energy and water, etc.).

The Dunkirk basin is home to many CO2 decarbonisation and use solutions and has deployed France’s first CO2 and H2 Hub.