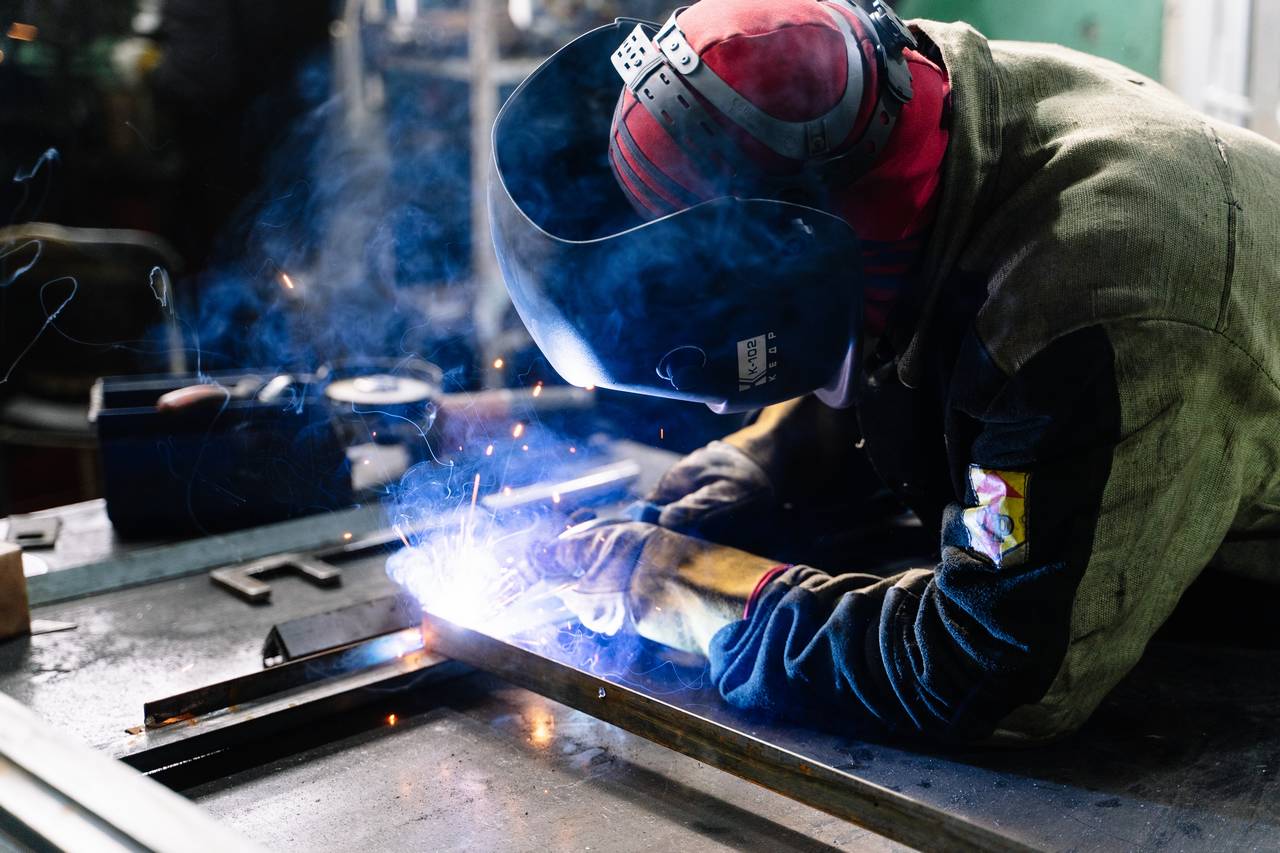

Metal and steelmaking industry

HISTORIC KNOW-HOW, A LOW-CARBON FUTURE

Like chemicals, the metallurgy and steel sectors have been established on the industrial-port platform for many years. Dunkirk is home to world-renowned companies and know-how.

Metallurgy and steelmaking are today at the heart of decarbonization issues, which is why the territory is emerging as a laboratory of solutions with numerous initiatives carried out by all socio-economic players.

The presence of these industries brings many opportunities, in particular thanks to the establishment of the 1st CO2 and H2 Hub in France.

Find out why Dunkirk is home to so many projects in the metallurgy and steel industries.

The metallurgy and steel industry is the largest private employer in the Dunkirk employment area.

The metallurgy industry accounts for more than 3,800 establishments in the Hauts-de-France region, representing a quarter of all industrial establishments.

The Flanders-Dunkerque region is the leading hub for industrial mechanics, industrial maintenance, and industrial services in the Hauts-de-France region.

The Dunkirk basin is home to more than 10 major international companies in the metallurgy and steel industry.

A dense network of industrial subcontractors

The presence of major players in the metallurgy and steel industries in the industrial port area is complemented by that of consulting and engineering firms and high-performance industrial subcontractors.

Here are a few examples:

- ADF Tarlin: a company specializing in industrial maintenance. It also operates in the fields of engineering and expertise, the supply of production and testing equipment, and finally in production and maintenance services.

- EKIUM: a design and engineering firm with expertise in a variety of fields such as steel, metallurgy, recycling, the environment, energy, etc.

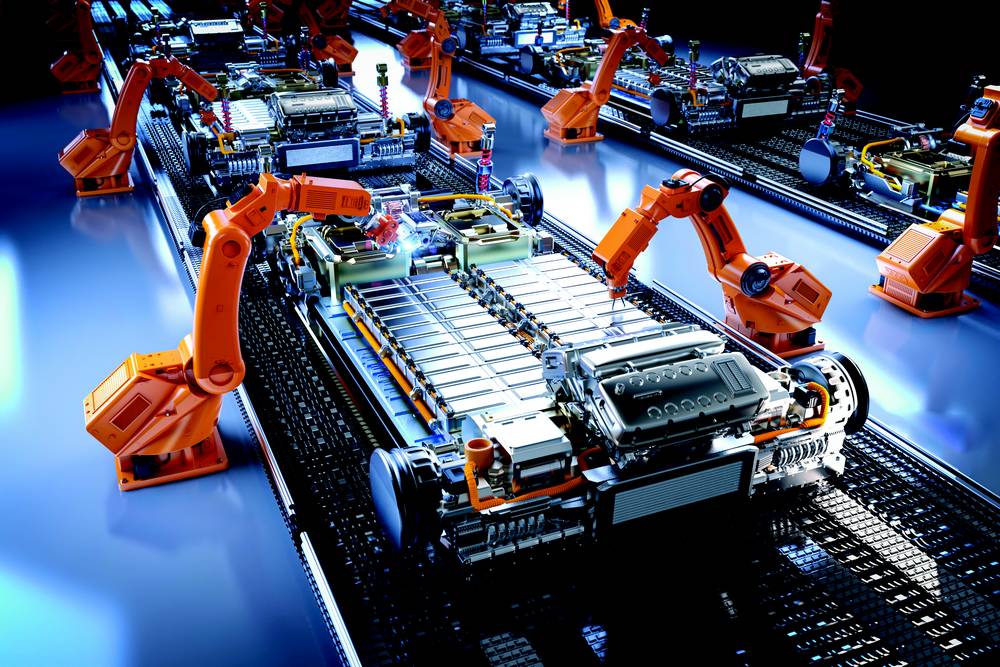

Aluminium in electro-mobility

Lightweighting with aluminium is a perfect solution for sustainable mobility

As car manufacturers and society put more and more focus on sustainablility, aluminium is the very good solution due to its lightweight and infinitely recyclable properties.

Aluminium extrusion are used to lightweight many parts of a car from crash management systems to battery closures, but also in engine blocks, transmission components or structural parts. Aluminium sheets are extensively used in hoods, doors and heat exchangers too.

Aluminium make the vehicles safer : it absorbs twice as much crash energy per kilogram as a steel solution.

The manufacturing methodology of aluminium extrusions offers a design flexibility that together with aluminium sheet and casting components makes aluminium the preferred solution for safety-critical components like battery boxes and bumpers.

Key information :

- Aluminium is light

- Aluminium offers good flexibility

- Aluminium is recyclable : recycled aluminium uses only 5% of the energy required to produce primary aluminium